Cylindrical screen printing

Cylindrical screen printing

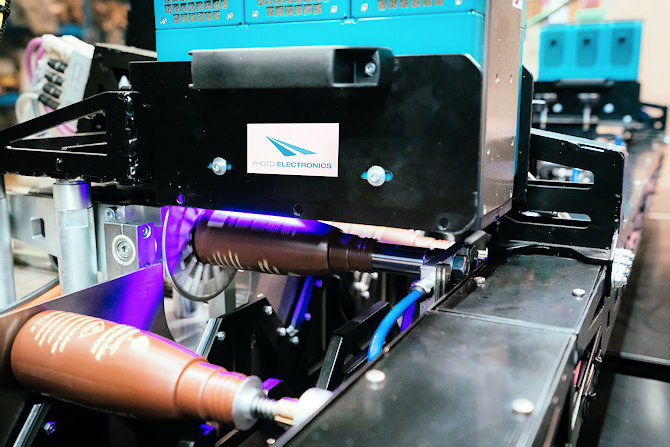

On the automatic silkscreen printing machines for the decoration of cylindrical objects, UV LED Droled L70 lamp allows to reach high productivity values. By positioning the lamp after each screen printing ink application, it can be polymerized completely during the rotation phase and allows you to immediately switch to subsequent decoration step.

UV Led lamps DROLED on brushless screen printing machine

UV Led DROLED lamps Photo Electronics employed on a brushless silkscreen printing machine for the decoration of cylindrical containers. The machine uses two UV lamps LED Droled for the complete polymerization of the ink after the printing phase. UV Led lamps switching on and off is immediate: this allows to keep it turned off during the interval between one press and the next, reducing power consumption.

UV LED Droled lamp installed on an automatic screen printing machine for printing cylindrical containers

Droled L70 with its partialized emitting window allows you to adjust the switching on/off and the intensity of certain segments of the lamp, based on the required printing width.

See the videos on Youtube

LED dryer for the polymerization of LED inks on containers, printed by semi-automatic machines

Combined with the semi-automatic screen printing machine, it completes the printing and curing process of the container

CYL STATION consists of a loading/unloading automatic carriage and a curing chamber withDROLED UV LED lamps.

All operational settings such as operating cycle data, intensity of the lamps and the details of the container, are managed easily through the touch screen.

See the videos on Youtube