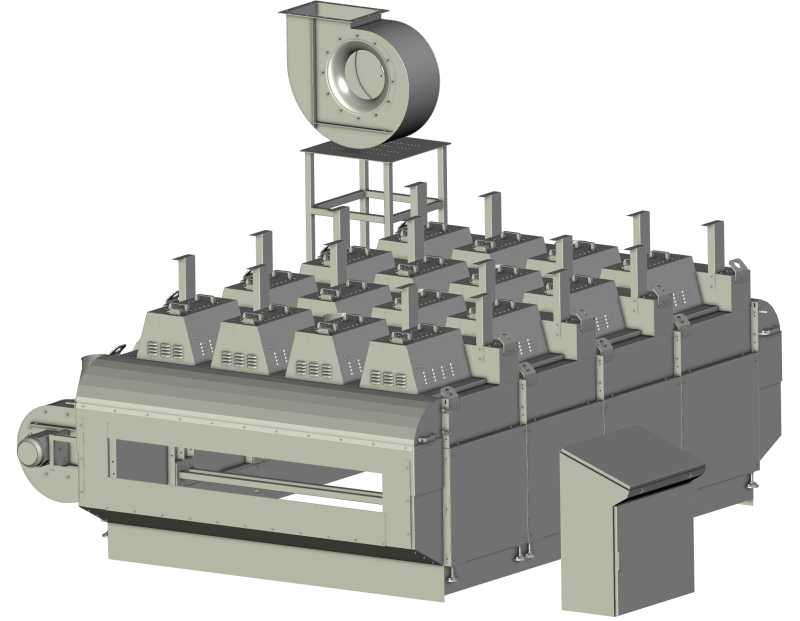

Specific UV ovens for the stone industry, for slabs and tiles

Productivity, versatility, safety and energy saving: these are the specific needs of the customer who requires a new in-line oven for the polymerization/hardening of single-component UV resins and fillers, in the production of marble and agglomerate slabs and tiles.

Photo Electronics, thanks to its more than decades of experience in the design and production of UV ovens, is able to fully satisfy all the requirements and all the UV ovens manufactured to date are highly appreciated by operators in the sector.

PDF Catalog

Download our product catalogue clicking here

Ask for information

Our experts will help you find the solution that best suits you.

Tecnical specifications

-

Hig curing speed: after40 seconds marble can be immediately polished

-

Specific UV resin: high hardening depth and no mixing

-

UV mastic can be retouched or added before the introduction of slab/tile into the oven, without hardeninig

-

UV mastic when polished is more brilliant than the two-component type

-

Enviroment and material temperature does not affect the hardening speed

-

Lower emission of volatile substances (VOC) in the environment (styrene or similar products)

-

Lower energy consumption compared to conventional ovens heat producers

Fields of application

-

Surface treatment of marble and stone natural and artificial

-

Marble tiles and slabs imperfections filling by single component resins

CONSTRUCTION FEATURES

- An electrical board (specific) lets the user manage the oven.

- The Oven is independent from the conveyor system. Infact, it is designed to adapt to any kind of roller conveyor or rack and can be moved or fixed.

- An integrated blower permits to extract and expel fumes generated by resins and channel them to the outside or to a solvents suppression system.

- An additional cooling system rationally distributes clean air for cooling the lamp units, air which can be taken from outside the building.

- They are designed in compliance with the Machinery Directive 98/37/EC and ATEX 94/9/EC.

- Each lamp unit is easily removable without the use of tools, and this allows to easily inspect the interior of the tunnel.

- A safety devices switch off each Lamp Unit if it is raised while operating.

- With the line stopped,ovens are automatically switched to reduced power to further limit energy consumption.

- The resin surface is irradiated homogeneously evenly over the entire width, both in case of slabs and tiles.

The control panel on the oven lets you:

- Turn each single lamp on/off, monitor the duration with a counter- Check the machine functions properly and any anomalies.

- The extraction system integrated into the oven allows you to expel the vapors generated by chemical products.

SAFETY

- UV Ovens reduce the waste of energy and solvent styrene emissions- Single-component products produce lower emissions of Volatile Organic Compounds (VOC).

- The fast hardening creates a barrier against solvent evaporation

Photo Electronics ovens are fitted with all the screens and covers necessary to protect the work environment from UV rays. Safety first,always.

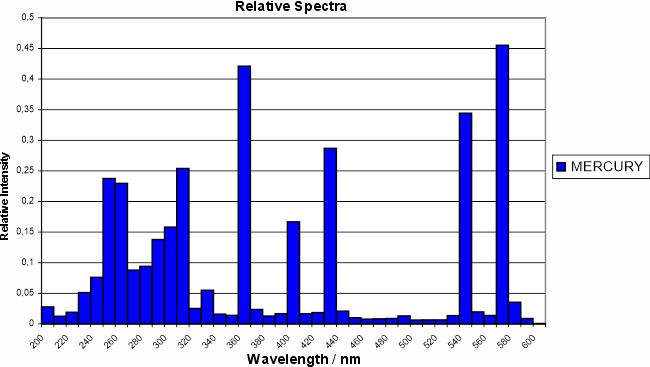

The metal-halogen lamps installed are available in 3 different UV radiations for perfect compatibility with the various types of resins available on the market.

1) Gallium Doped lamp

2) Iron Doped lamp

3) Mercury lamp